Understanding Heat Pump Systems in Chantilly Homes

Heat pumps have become increasingly popular in Chantilly, MD, where seasonal temperature variations demand efficient heating and cooling solutions throughout the year. These versatile systems transfer heat rather than generate it, making them remarkably energy-efficient compared to traditional HVAC systems. At Richard's Heating & Air Conditioning Co., Inc., we specialize in diagnosing and repairing all types of heat pump issues that homeowners in the Chantilly area commonly encounter. Since 1959, Richards Heating & Air Conditioning Co. has been designing, installing and servicing residential air conditioning and heating systems in the Washington Metropolitan area, giving us unparalleled expertise in understanding how local climate conditions affect heat pump performance.

The unique humidity levels and temperature fluctuations in Chantilly can place additional strain on heat pump components, leading to specific wear patterns that require experienced technicians to identify and address. Our comprehensive approach to heat pump repair involves thorough system diagnostics, component testing, and performance optimization to ensure your system operates at peak efficiency year-round.

Common Heat Pump Problems We Repair

Heat pumps in Chantilly frequently experience issues related to refrigerant levels, electrical components, and mechanical wear. Low refrigerant levels often manifest as reduced heating or cooling capacity, ice formation on outdoor units during winter operation, or unusually long run times that fail to achieve desired indoor temperatures. We utilize precision gauges and electronic leak detection equipment to identify refrigerant leaks, which commonly occur at connection points, service valves, or within the evaporator and condenser coils themselves.

Electrical problems represent another significant category of heat pump repairs we handle regularly. Faulty capacitors can prevent the compressor or fan motors from starting properly, while worn contactors may cause intermittent operation or complete system failure. Defrost control boards, particularly crucial during Maryland winters, can malfunction and prevent the system from properly removing ice buildup on outdoor coils. We maintain extensive inventories of replacement electrical components to minimize downtime when these critical parts fail.

Our Diagnostic and Repair Process

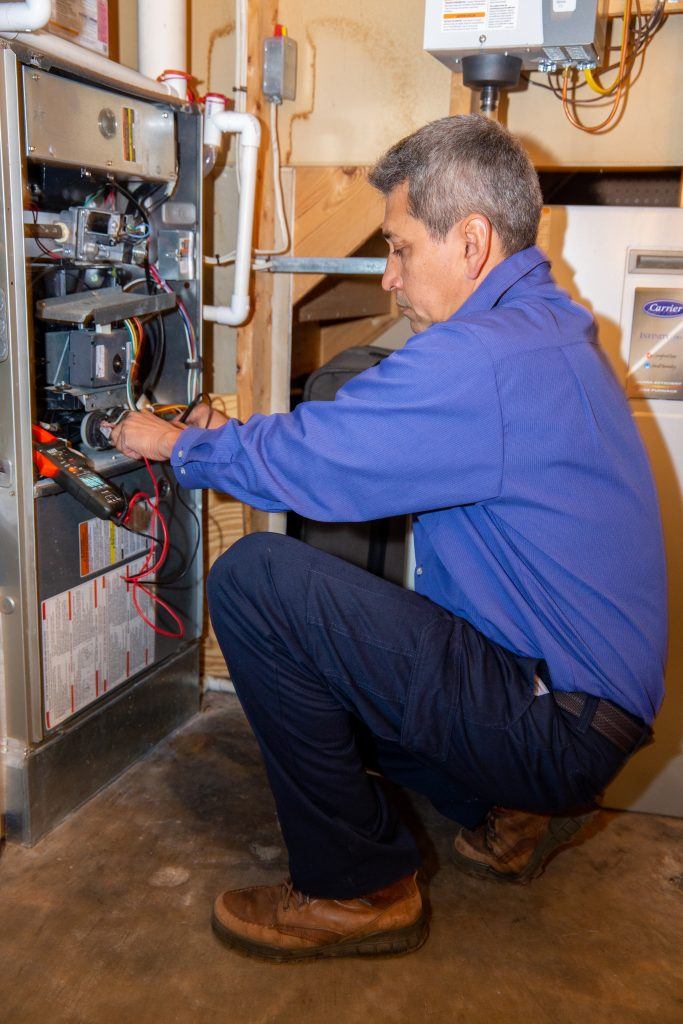

When you contact Richard's Heating & Air Conditioning Co., Inc. for heat pump repair services in Chantilly, our certified technicians begin with a comprehensive system evaluation. This process starts with listening to your concerns and documenting any unusual sounds, odors, or performance issues you’ve noticed. We then perform a visual inspection of both indoor and outdoor units, checking for obvious signs of damage, wear, or improper installation that might contribute to system problems.

Our diagnostic procedures include measuring system pressures, testing electrical components with specialized meters, checking airflow rates across coils, and evaluating thermostat operation and settings. We install “total comfort conditioning” systems to meet the unique configurations of individual homes, recommending systems that fit each customer’s needs, and this same customized approach extends to our repair services. Temperature differential measurements between supply and return air help us assess overall system efficiency and identify potential issues with heat transfer capabilities.

Reversing Valve and Defrost Cycle Issues

The reversing valve represents one of the most critical components unique to heat pump systems, allowing the unit to switch between heating and cooling modes. When this valve fails or becomes stuck, homeowners in Chantilly may find their system blowing cold air during heating season or warm air when cooling is needed. Our technicians test reversing valve operation using specialized procedures that verify proper refrigerant flow direction and solenoid coil functionality.

Defrost cycle problems particularly affect Chantilly homes during winter months when outdoor temperatures hover near freezing. Malfunctioning defrost controls can lead to excessive ice accumulation on outdoor coils, dramatically reducing heating efficiency and potentially causing compressor damage. We evaluate defrost timing circuits, temperature sensors, and pressure switches to ensure proper defrost initiation and termination, optimizing system performance while minimizing energy consumption during these necessary defrost periods.

Component Replacement and System Optimization

- Compressor repairs and replacements: We diagnose compressor failures through comprehensive electrical testing and pressure analysis

- Fan motor services: Both indoor blower motors and outdoor fan motors receive thorough testing and lubrication

- Coil cleaning and treatment: Dirty coils reduce efficiency by up to 30 percent and accelerate component wear

- Control board diagnostics: Modern heat pumps rely on sophisticated electronics that require specialized testing equipment

- Refrigerant line repairs: We identify and repair leaks while ensuring proper insulation and protection

At Richards, we are proud of our work and are dedicated to maintaining a reputation in the industry and the community as reliable experts. This commitment means we don’t just replace failed components; we investigate underlying causes to prevent recurring failures and optimize overall system performance.

Preventive Maintenance Benefits

Regular maintenance significantly reduces the likelihood of unexpected heat pump failures that leave Chantilly homeowners without heating or cooling when they need it most. Our maintenance services include comprehensive cleaning of indoor and outdoor coils, which improves heat transfer efficiency and reduces operating costs. Filter replacement schedules vary depending on home conditions, but neglecting this simple task forces systems to work harder, increasing wear on all components.

Electrical connection tightening prevents resistance-related failures that account for approximately 25 percent of heat pump service calls. Lubricating motor bearings extends equipment life while reducing operating noise that often indicates developing problems. Richards is a fully licensed and insured mechanical, gas fitting, and electrical contractor, ensuring all maintenance and repairs meet or exceed industry standards and local code requirements.

Energy Efficiency Considerations

Heat pump efficiency ratings have improved dramatically over recent decades, with modern units achieving heating seasonal performance factors exceeding 10 HSPF and cooling ratings above 20 SEER. When repairing older heat pumps, we evaluate whether continued repairs remain cost-effective compared to upgrading to newer, more efficient equipment. Energy savings from improved efficiency often offset replacement costs within five to seven years, particularly for systems over fifteen years old.

Proper refrigerant charge proves critical for maintaining rated efficiency levels. Undercharged systems work harder to achieve desired temperatures, increasing electrical consumption and accelerating wear. Overcharged systems experience liquid refrigerant flooding back to compressors, potentially causing catastrophic damage. Our technicians use subcooling and superheat calculations to verify optimal refrigerant levels for maximum efficiency and reliability. Contact us today.